STS Shredded Scrap

Business Areas

Our 5,000-horsepower shredder equipment provides high-quality stainless steel scrap processing.

The shredding process cuts large scrap into uniform sizes, maximizing the efficiency of recycling operations. This core technology enables the stable supply of high-purity and high-quality materials required by casting and other industries.

Shredded Features

- 1. Optimized Size and Uniform Quality

-

- Shredding scrap into uniform sizes improves operational efficiency in the process.

- Effective removal of foreign substances minimizes impurity generation during recycling.

- 2. Enhanced Logistics and Storage Efficiency

-

- Reduced volume decreases transportation and storage costs.

- Provided in a compact form to improve working conditions.

- 3. Environment-friendly and Sustainable Resource Utilization

-

- Supplying eco-friendly raw materials to reduce carbon emissions.

- Enhancing scrap recycling to build a circular economy.

- 4. Customized Solutions for Customers

-

- Providing customized scrap supply tailored to various industry needs.

- Establishing quality control and supply systems that match customer specifications.

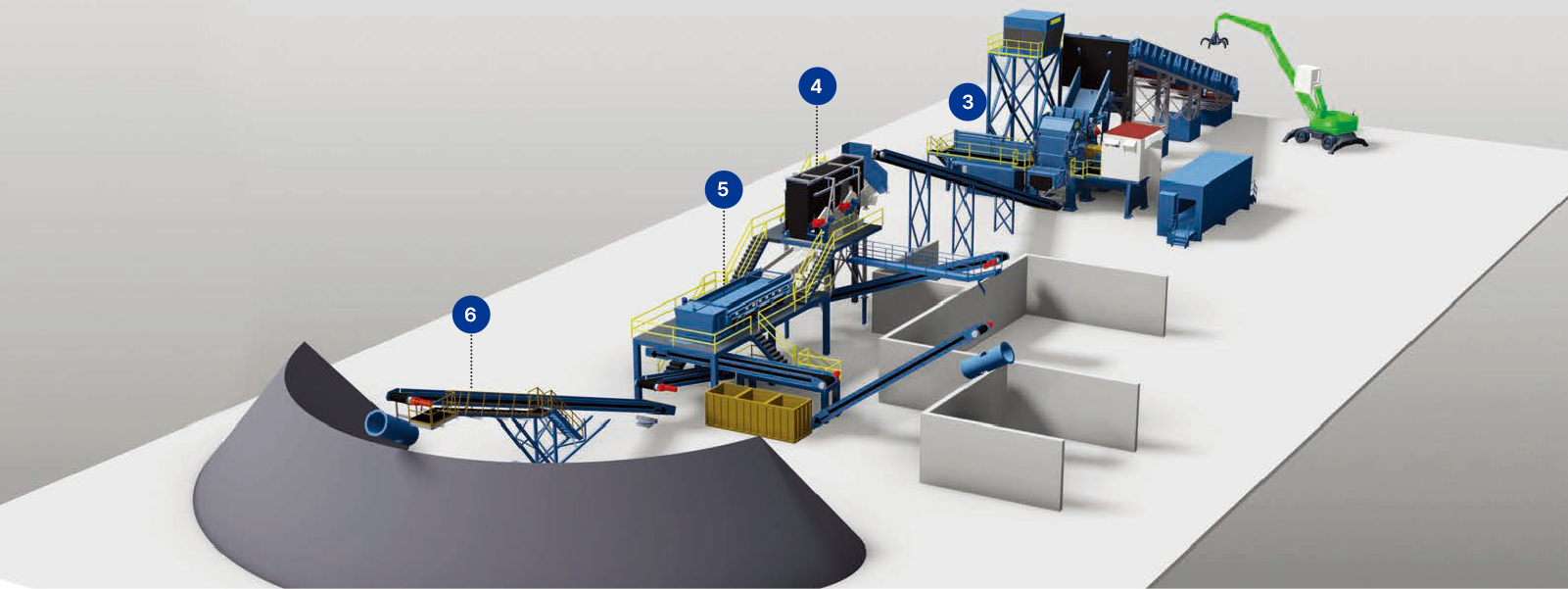

Production Process

- 1Inputting raw scrap

- 2Shredding and sizing

- 3Removal of metal particles and impurities (cyclone)

- 4Magnetic separation

- 5Final inspection and sorting

- 6Discharge

Production Process

1Feeding

2Shredding / Sizing

3Dust Collection System

4Magnetic Separation

5Manual Sorting

6Final Discharge